|

|

|

#22 |

|

Tri-State Post Whore

|

well I've had a lot of practice at work and brought some scraps home today to give pipe welding another go.

monday and tuesday i did 20 or so sets of these tips, started off real terrible, and this was one of the last ones i did   welding in that tight spot was tough, especially cuz i can only move in one direction at the moment, and the thick cast stainless to thin tips was a challenge in its own heres how i did when i got home, they're better then i have been doing (or at least i think so) but it looks to me like every once in a while i get a heavy right foot and get the material too hot, but the thinner filler wire has worked magic as far as being able to dip properly, also figuring out how to "pulse" the pedal, but mine doesn't have too much travel, i need to upgrade to the miller pedal since mine is the hobart one, it should be interchangeable.     let me know what you'd guys think |

|

|

|

|

|

#23 | |

|

Tri-State Post Whore

|

Don't get into the habit of manually pulsing the pedal, you're going to have all sorts of issues doing that. I only do that when I am in a REALLY tight spot and having trouble filling correctly, but it's more so that I don't burn through than to get nice beads.

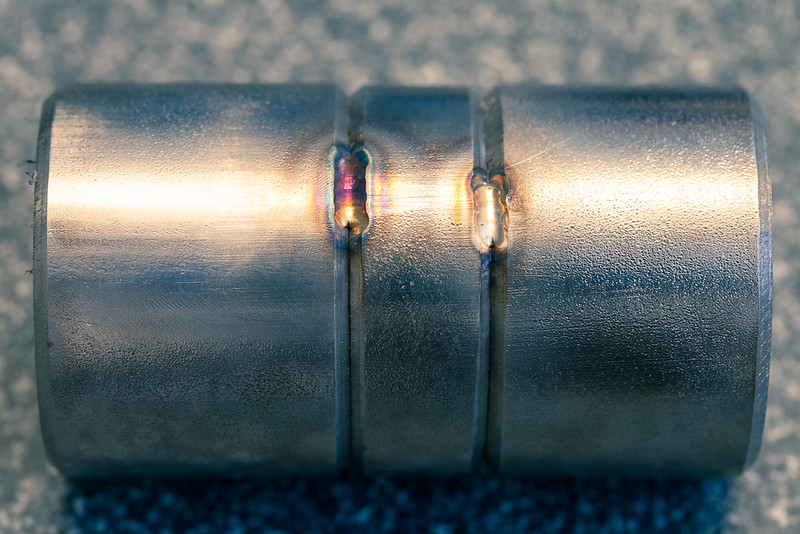

You're getting there, keep practicing. Try working with like 1/8" plate and learning how the puddle moves and whatnot, tube is really really hard to learn on because it's always changing and it's very thin. Also remember, metal heat soaks. So when you start out you'll be rolling with more heat, then you'll need less and less as it gets hotter and hotter. I like to try and focus on the bead width, making it the same every time and making sure that when I drag the puddle forward I push it dead straight. Then, when you think you're getting pretty good, turn on AC and get your ass handed to ya. :P Here's some collector welds for my turbo manifold, getting better now.

__________________

Champ White 1996 Civic Hatch - To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. Quote:

|

|

|

|

|

|

|

#24 |

|

Tri-State Post Whore

|

thanks again aaron, the only reason i do tube is because since i work for an exhaust shop i figure i might as well learn on the pipe since we rarely have anything flat in the scrap bin, ill have to pick up some steel filler/ steel plate, right now i only have stainless. but thanks for the tips, your welds look professional for sure! gonna practice a little bit this afternoon ill edit this post with pics

|

|

|

|

|

|

#25 |

|

Tri-State Post Whore

|

the past 2 weekends i've been building a brew stand, it's certainly not as pretty as any of the work posted so far, but it's my first metal fabrication project and i think it came out great!

I need to finish up the fuel system, and then wire in a pump.

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. |

|

|

|

|

|

#26 |

|

Tri-State Addict

Join Date: May 2010

Location: Upper Gwenydd

Member #16558

My Ride: 00 VW Jetta Vr6, 97 Audi A4, 84 VW Rabbit Vert. Vr6, 81 VW Rabbit diesel truck, 81 VW Rabbit Hatch iTrader: (0)

|

ImageUploadedByTapatalk1337719596.660872.jpg

Unfortunately I had to get a new phone so this is the only pic of the skid plate I welded onto my oil pan for the vr6 I just put in the car. It was rushed after work but overall I'm happy with it, i did clean it up a bit and sand it down to make it look better. Using an old 1960's Lincoln water cooled tig machine no special features like they have today just put your foot in it and go. Sent from under my car. |

|

|

|

|

|

#27 |

|

Tri-State Post Whore

|

havnt updated in a while, no cool projects quite yet, but i have one in the making. spent the past 2 days at work making various brackets for our products. my welds are very consistent now and i think i have it figured out for the most part. one of the guys i work with told me that instead of trying to move super fast to keep the heat from soaking, to simply just push more filler in on each dip, and it def helped tons!

|

|

|

|

|

|

#28 |

|

Tri-State Addict

|

Seems like you are still "learning the pedal", much improvement tho, keep up the good work.

Heres a drill that helped me, Just get a piece of scrap sheet metal, and run an arc across it. No filler rod, just use the torch, and pedal control to create a nice consistent seam down a piece of metal. Try to acheive 100% penetration, without burning through, while keeping your heat pattern consistent as well. You'll learn to "read" read the puddle faster, and adjust yourself quicker as the base metal heats up and the arc changes.

__________________

2001 Dakota Quad Cab, 1996 Ford F250, 1993 Honda Civic, 1991 Eagle Talon, 1970 Plymouth Duster. |

|

|

|

|

|

#29 | |

|

Tri-State Post Whore

|

Quote:

|

|

|

|

|

|

|

#30 | |

|

Tri-State Post Whore

|

Getting better! Definitely improving. Just keep up with the torch time and you'll learn more and more. You're just a bit cold on that bracket though, but that feel will all come with time.

I learned something new just yesterday. Been reading about how to weave but never really had to do it before until now. They're a ton of fun, and I think it came out pretty nice for my first go. Still need to go the rest of the way around, and I'm bound to screw it up so I figured I'd take pics of the good part. :P

__________________

Champ White 1996 Civic Hatch - To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. Quote:

|

|

|

|

|

|

|

#31 | |

|

Tri-State Post Whore

|

Quote:

Did tony really get you guys those rotisserie things that spins around on the work benches? I was In a meeting with him Monday and he was talking about them.

__________________

135

├┼┼╕ 246R |

|

|

|

|

|

|

#32 | |

|

Tri-State Post Whore

|

Quote:

getting better, but i start stop a lot and of course still stick the tungsten all the time. but as billy says. "you need to get more consistent. but with more practice you'll get consistently better" speaking of practice, i also put a flange on a buddys exhaust for his turbo build and it came out really nice.  but its a little easier when you have a real thinck flange to keep the heat on. as always I'm just gonna keep practicing. really determined to master the welding. fabricating is always fun for me. even though i still struggle a bit with most of it

Last edited by rocknrace03; 07-18-2012 at 06:12 PM. |

|

|

|

|

|

|

#33 | |

|

Vendor

|

Quote:

__________________

MISHIMOTO AUTOMOTIVE --Push the Limits-- [ To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. | To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. | To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. | To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. | To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. ] The Leader in Aftermarket Performance Cooling Technology Offering Aluminum Radiators, Intercoolers, Silicone Hoses & Cooling Accessories |

|

|

|

|

|

|

#34 | |

|

Tri-State Post Whore

|

Quote:

Wait until you see tony and sal throw a mask on... Then your I'm for a treat!

__________________

135

├┼┼╕ 246R |

|

|

|

|

|

|

#35 |

|

Tri-State Post Whore

|

|

|

|

|

|

|

#36 |

|

Tri-State Post Whore

Join Date: Apr 2006

Member #1721

My Ride: 92 BMW 525, 95 BMW 525, 87 BMW 325, 95 BMW 530 iTrader: (0)

|

I recently picked up a miller diversion 180 and converted it to a weldcraft wp9 torch with crazy awesome flex hose

Anyway, here are some of my welds  Autogenous Weld Root Pass by Jon Kensy, on Flickr I also built this tool to bevel pipe  Pipe Beveler Project by Jon Kensy, on Flickr

__________________

1986 BMW 325E -- 1992 BMW 525i -- 1995 BMW 525i -- 1995 BMW 530i |

|

|

|

|

|

#37 |

|

Tri-State Post Whore

|

nice! any info on that mod. i have a hobart 165 ez-tig (same as the diversion 165) we use those hoses at work which i really like having. would love to see if its possible on my machine for home. and your welds are super nice. sooo jelly

|

|

|

|

|

|

#38 | ||

|

Tri-State Post Whore

|

Quote:

PS, you're planning on running another bead right? Way undercut as of this moment.

__________________

Champ White 1996 Civic Hatch - To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. Quote:

|

||

|

|

|

|

|

#39 |

|

Tri-State Aficionado

|

Do gay little end tables count??

My dad's a welder and taught me to TIG weld years ago. But all I used it for, beyond practicing on scrap, was some gay little end tables I made for my bedroom using silver(plated) serving trays I got at a flea market. ...Basically if Martha Stewart had a welding episode, this would be it. |

|

|

|

|

|

#40 | |

|

Vendor

|

Quote:

__________________

MISHIMOTO AUTOMOTIVE --Push the Limits-- [ To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. | To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. | To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. | To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. | To view links or images in signatures your post count must be 10 or greater. You currently have 0 signatures. ] The Leader in Aftermarket Performance Cooling Technology Offering Aluminum Radiators, Intercoolers, Silicone Hoses & Cooling Accessories |

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| fabrication material store? | Keeper1343 | Networking: requests and offers | 7 | 05-23-2011 08:23 PM |

| Custom Fabrication! | PSIPROformance | PSI PROformance | 0 | 04-08-2011 02:03 PM |

| Interior fabrication...upholstery | wrxbert | Networking: requests and offers | 6 | 02-14-2010 01:59 AM |

| Roll Cage Fabrication service Available... | Jfaphoenix32 | (Past Vendors) | 12 | 01-02-2009 11:24 PM |